Hardisty Operational Crude Tank

原油储罐的安装Hardisty管道Terminal

Husky Midstream | Hardisty, Alberta, Canada | 2019-2020

Installation of a500,000 bbl tank

Increased the maximum tank height from14.6 metres to 24.4 metres

Design of three nominal pipe sizeNPS 36 pipelines

Challenges

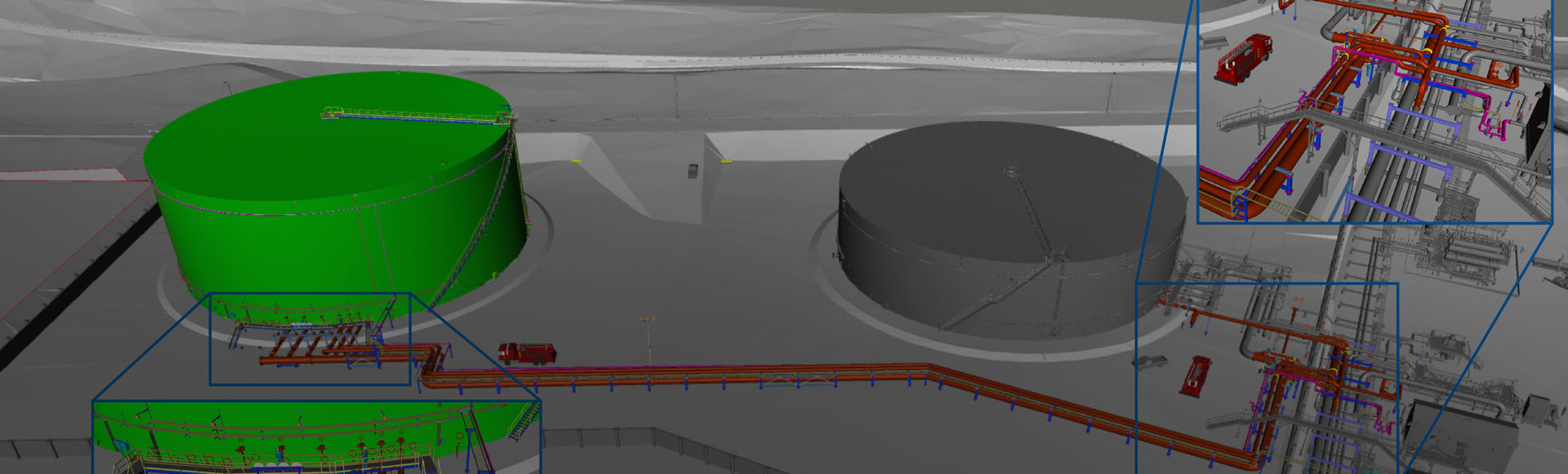

- The Hardisty Operational Crude Tank includes the installation of a new crude oil tank at the North Campus at the Hardisty Pipeline Terminal.

- The Hardisty Terminal is part of the Hardisty Pipeline Complex which includes various major terminal and pipeline operators.

- The scope of this project is to add a 500,000 bbl tank, complete with internal Sandborn floating roof.

Solutions

- This tank will be connected from the existing inlet/outlet piping already constructed within the tank cell to the North Campus section of the Hardisty Terminal.

- The tank will be installed in a common containment berm with an existing 300,000 bbl nominal capacity tank. Both tanks will receive and store Lloydminster Blend (LLB) crude from LLB Midpoint and Wainwright pipelines.

- Also included in the scope is the installation of three nominal pipe size NPS 36 pipelines by HDD method from the North Campus to the South Campus.

Highlights

- The construction of the operational tank is being completed in the same time frame as an additional two 500,000 bbl tanks. These tanks will be located in a common, expanded tank cell.

- Significant pre-fabrication work was completed off-site to enhance early in-service date.

- All design aspects of the project were completed with continual support and input from field operations.

Related Projects

What's your challenge?

Related Projects

AP60 Smelter

Canada

Hell’s Kitchen Integrated Lithium and Power Project

Imperial Valley, California, USA

Vesta SWX Facilities & Pipeline

Alberta, Canada

Pump Station VFD Replacements

Alberta, Canada

Grand Falls Dam and Spillway Rehabilitation

Grand Falls, Newfoundland, Canada

Rosslyn Brewery Cogeneration Plant

South Africa

Mesquite Solar 1

United States of America