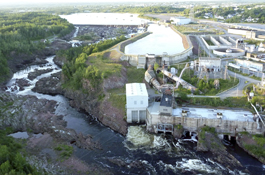

Keenleyside Dam Spillway Gate Improvements

Enhancing the safety and reliability of a vital dam on the Columbia River

BC Hydro | Canada | 2007–2015

Increasedreliability resulting in enhanced downstream flood protection

Enhancedseismic-withstand capability

Improvedflow control for the entire Columbia River system

Challenge

- Make improvements to the spillway, structures, and associated ancillary equipment of the 48-year-old Hugh L. Keenleyside dam, which has a consequence classification of “Extreme.”

- Complete this as part of an ambitious plan to upgrade the reliability of spillway systems at BC Hydro’s fleet of dams across the province.

- Improve the spillway gate system and enhance the seismic-withstand capability without interrupting crucial operations.

Solutions

- As owner’s engineer and as part of an EPC team, we collaborated with the contractor and owner to create customized, functional, and practical solutions.

- Provided the design solutions to increase spillway reliability and upgrade seismic resistance to current standards.

- Incorporated robust equipment, redundancy, increased protection and control instrumentation, as well as segregation and separation of critical cabling and components.

Highlights

- Due to their tremendous size (more than 200 tonnes each), it was decided to refurbish the spillway gates in-situ.

- To accomplish this safely, an approach was proposed that used an anchor point on the hoist platform, steel and four grommet anchor tabs at the center of the drum’s cylinder.

- This simple, efficient idea locked the drum and prevented the gate from moving, allowing them to be worked on safely while suspended from the hoist.

- This solution was accepted by WorkSafe BC and saved a considerable amount of time and money.

"The project has been assessed and is considered to have improved the overall spillway gate reliability at this important facility by at least "an order of magnitude.” This was accomplished through Hatch’s effective design solutions, which incorporate robust equipment, redundancy, increase protection and control, segregation, and separation of critical features. Improved safety for the public and for BC Hydro employees is the result."

Project numbers

42-metre-highdam

8 submergedlow-level outlet gates refurbished

4泄漏wayoperating gates refurbished

200 tonnes each:weight of the spillway operating gates

12 gate hoistsrefurbished

What's your challenge?

Related projects

Grand Falls Dam and Spillway Rehabilitation

Grand Falls, Newfoundland, Canada

Kelso Dam: urgent repairs and rehabilitation project

Milton, Ontario, Canada

Oxec II Hydroelectric Project

Guatemala

Niagara Tunnel

Canada