Keswick Water Pollution Control Plant Upgrades and Outfall

Providing better water-pollution control without disrupting community and environment

Regional Municipality of York | Canada | 2006–2014

First tertiary ultrafiltration membrane in Ontario

Outfall construction with open-cut trenching, microtunneling, marine dredging

Winner of multiple awards

Challenges

- Designing, constructing and commissioning the new expanded water pollution control plant (WPCP) took place while the existing WPCP remained operational.

- A tight phosphorus discharge limit for Lake Simcoe had to be met at less than 0.1 mg/L.

- The outfall project faced challenging soil and groundwater conditions.

- The location of the project meant a busy five-corner intersection had to be negotiated and a critical utility crossed under with less than 0.5 metres of separation.

Solutions

- The project's primary objectives were to increase the treatment capacity of the Keswick WPCP by 50 percent from an average of 12,070m3/d to 18,000m3/d.

- It was recommended that state-of-the-art tertiary ultrafiltration (UF) membrane bioreactor technology be used in the design of the plant's expansion. This technology can reliably and consistently deliver the very low phosphorus limits that were required.

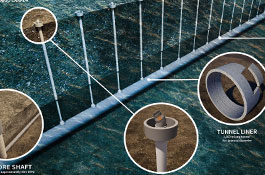

Outfall project:

- 主要目标是完成twinning of the existing effluent outfall with minimal impact to the community and the environment while minimizing schedule and cost.

- Microtunneling allowed the outfall to be constructed beneath busy intersections and along quiet residential streets with a minimal impact to residents and traffic.

- Microtunnel construction methods preserved the existing mature trees along the alignment, eliminated the need to import aggregates for trench backfilling, and allowed the onshore-to-offshore transition to be completed with a minimal impact on the sensitive near-shore aquatic habitat.

Highlights

- The cold-weather-membrane performance testing conducted at the Keswick WPCP set the benchmark for tertiary membrane wastewater treatment technology applications in Ontario and Canada.

- Unlike greenfield construction, the plant expansion was a dynamic process due to constantly changing demands of the operating facility. Construction of the project involved approximately 80 staff and 20 equipment suppliers/installers during peak conditions, all working concurrently and in tandem.

- Several notable microtunneling firsts were achieved on the outfall project, including it being:

- the first underwater reception of a microtunnel drive in Canada;

- the first curved microtunnel drive in Canada; and

- the first spatial curve (simultaneous plan and profile curve) microtunnel drive in North America.

Outfall Project Awards:

- APWA 2014 Public Works Project of the Year, Environment Category, US$5 million to US$25 million

- OPWA 2013 Public Works Project of the Year, Structures Category, over C$20 million

- ACEC New Jersey Chapter 2014 Honor Award Winner

- Runner Up, 2013 North American Trenchless Project of the Year (New Installation)

- 2013 International Engineering Project of the Year, Irish Building and Design Awards

WPCP Award:

- 2015 Award of Excellence , CEO Awards

Project numbers

Increasing the WPCP's average day flow of12,070m3/dto18000立方米/天Project cost ofC$54.5 millionfor the WPCP expansion

Project cost ofC$20 millionfor the outfall project

Overall length of the outfall is approximately1,800 metres, of which900 metresis on-shore and900 metresis offshore.

Services & technologies provided

How we can help you

If you have a problem that needs to be solved, please get in touch.

Related Projects

水sampling at depth with drones

Canada, USA

Burnhamthorpe Water Project

Canada

Al Taweelah Alumina power and steam integration

United Arab Emirates

uMshwathi Regional Bulk Water Supply Scheme Phase 2

South Africa

水Outfall Project—MBR System

United States

Eagle Point Mine

Canada

Ranger Brine Concentrator

Australia

See All