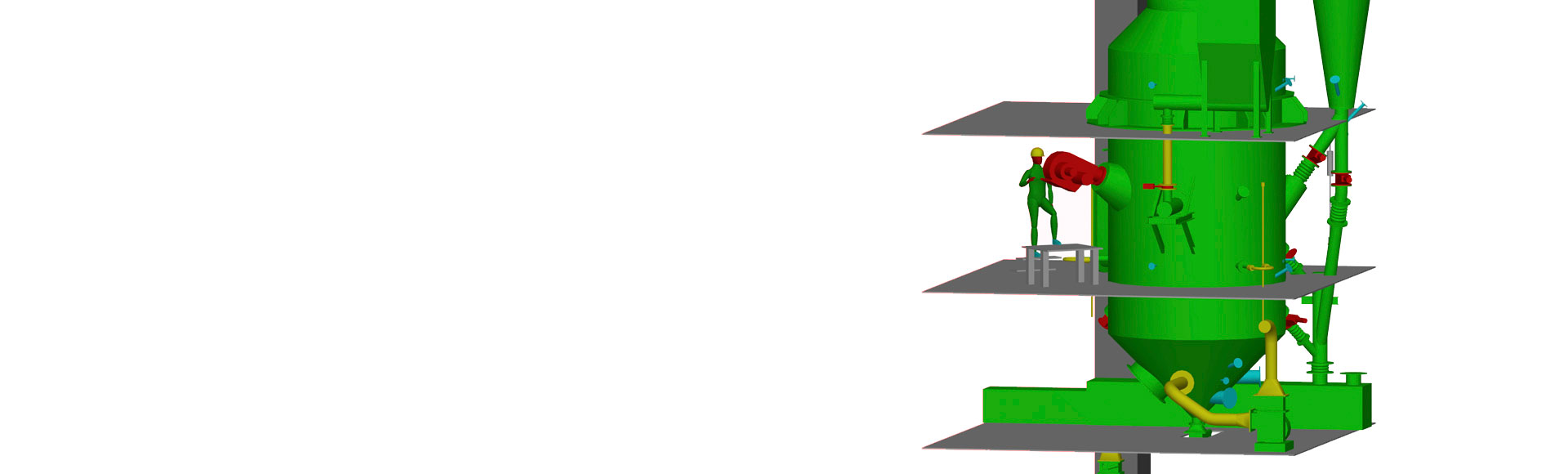

DST Demonstration Plant

Gold concentrate fluidized bed roaster

Dundee Sustainable Technologies (DST) Inc. (previously Nichromet Extraction Inc.) | Canada | 2013

1 tpd to 15 tpd

scale-up

700°C

design temperature

Brownfield

development

Challenges

- DST required a demonstration plant to further prove its patented gold-extraction process at an industrial scale of 15 tons per day. It wanted to show that its process could operate successfully at a much larger throughput than its pilot plant had been able to produce. As well, the pilot plant had operated in batches. This demonstration plant was being constructed to illustrate that the process could lend itself to continuous operation.

- This brownfield project had to be undertaken within the layout constraints of an existing facility.

Solutions

- A new pyrite fluid bed roaster, off-gas cyclone, and solids transfer system were designed by Hatch and installed at the pilot plant site.

- Complete thermal and structural modeling was undertaken for the roaster shell, roof, tuyere plate, grillage beams and windbox, and the off-gas cyclone.

- The fluid bed roaster was designed to include a moist-feed introduction system, simple bed cooling for temperature control, and cyclone fines recirculation.

Highlights

- Fluid bed roaster removes the sulfur, arsenic, and carbon in the feed material.

- The final design also offered a versatile and flexible operation, permitting the process to be adjusted to test a number of configurations.

- Roaster and feed system started up smoothly and within a week.

Project numbers

640°Croaster70°Cproduct screw cooler

15 t/daydemo plant

3,500engineering hours LTI-free