Dehydration Area & Core Technology Delivery Projects

Fluidized bed dryers boost production at high-altitude magnesium plant

Qinghai Salt Lake Industry Co., Ltd. (QSLIC) | China | 2010–2012

10-stage

fluid beds

30%

smaller vessels than predecessors

400°C

HCl gas

Challenge

- 现有的流化床干燥机需要回溯d for structural integrity and suitability at the new high-altitude project site, which was characterized by severe seismic zoning.

- The magnesium production-capacity target was 100,000 tpa, compared to the original production capacity of 48,000 tpa.

Solutions

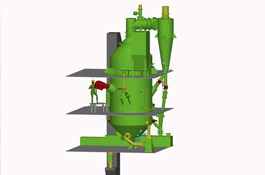

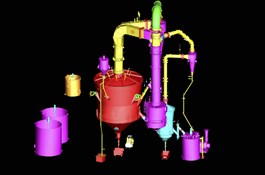

- To achieve the higher production capacity, the number of fluidized bed dryers was tripled for a total of six hot air dryers and six HCl gas dryers.

- Finite element-analysis modeling was used to verify and improve the mechanical design of the fluidized bed dryers, reducing costs.

- The feed distribution to each dryer stage was enhanced for more uniform mixing, increasing dryer efficiency.

- The internal components of the dryers were simplified and optimized to increase their efficiency, achieve production targets, and reduce costs.

Highlights

- The new air dryer design has a 30% smaller vessel diameter.

- It uses the fluidized bed area and materials of construction more efficiently, and has improved the air duct layout and maintainability.

- The two existing HCl dryers were refurbished with minor changes to enhance cost savings.

- Fluid bed dryers were designed according to the ASME Boiler and Pressure Vessel Code Section VIII.

Project numbers

100,000 tpamagnesium production capacity2-stagehot-air fluidized bed dryer

10-stageHCl-gas fluidized bed dryer

2,700 m海平面以上

400°Cdesign temperature