Kemano Second Tunnel (T2) Project

Enhancing the long-term reliability of renewable hydropower for aluminium smelter

Rio Tinto | British Columbia, Canada | 2017-2020

7.6 kmof newly-excavated tunnel

250,000 m3volume of rock to be excavated

Remote site accessible only by air or sea

Mountainous terrain with high avalanche risk

Challenges

- BC Works' Kitimat aluminium smelter relies on the guaranteed availability of a stable supply of hydroelectric power that the Kemano Powerhouse provides.

- Located 75 km southeast of Kitimat, British Columbia, Kemano is only accessible by air or sea.

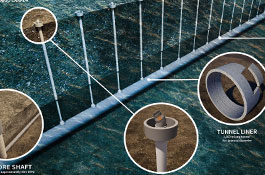

- The 960 MW Kemano Powerhouse receives water from the Nechako Reservoir through a single 16-km tunnel that is over 60-years-old.

- Rio Tinto recognized that a second 16-km tunnel was needed to ensure the long-term reliability of renewable power to the smelter in Kitimat.

- To connect the powerhouse to the reservoir, the new tunnel must be bored through the mountains in a high avalanche risk environment.

- Project construction will occur between 2018 and 2020—through two winter seasons where temperatures sit around minus -10 degrees Celsius and avalanches are common.

Solutions

- Hatch has been selected by Rio Tinto to provide the engineering, project, and construction management (EPCM) services for the project.

- 该项目包括挖掘一个新的porti 7.6公里on of tunnel and refurbishing an existing 8.4 km portion of the second tunnel to complete the 16 km-long tunnel to the existing penstocks.

- The second tunnel will allow Rio Tinto to conduct repairs and maintenance on the original tunnel without impacting power supply to Kitimat operations.

- The 1,300 ttl'ughustunnel boring machine (TBM) was purpose-built for the specific ground conditions of the project.

- A mechanical gate will be installed at the existing T2 intake at Tahtsa Lake, which will also have a lower environmental footprint than building a new intake.

- An avalanche control system (Gazex) will be implemented at critical points on the mountains to mitigate avalanche risk during project construction.

Highlights

- Rio Tinto has involved the Haisla First Nation and the Cheslatta Carrier Nation to ensure that indigenous cultures and traditions are respected.

- The Cheslatta Carrier Nation selected the name for the TBM—tl’ughus—after the legend of the giant monster snake that bored through the mountains, a story that shares many parallels with the T2 project. Students from the Haisla Nation participated in a contest to the design the artwork on the cutterhead of the TBM.

- Once complete, the upgrade is expected to take the 60-year-old Kemano generating station well beyond 100 years.

- The environmental team is introducing a number of controls to safeguard protected species in the area, including fish, amphibians, bears, and mountain goats.

- BC Works' Kitimat smelter produces aluminium with one of the lowest carbon footprints in the world.

Project Numbers

- CDN$600M project

- 300-person workforce at peak construction

- 7.6 km length of newly-excavated portion of second tunnel by TBM

- 190 m length of the TBM

- 3 worker camps

- 8.4 km refurbished portion of 1990s second tunnel

- 16 km length of completed second tunnel

- 250,000 m3 volume of rock to be excavated

How we can help you

If you have a problem that needs to be solved, please get in touch.

Related Projects

Mount Royal Tunnel double arch replacement

Montreal, Quebec, Canada

Minneapolis weathers the storm with a new parallel tunnel

Minneapolis, MN, USA

Burnhamthorpe Water Project

Canada

Vaudreuil 2022 ― Phase I

Canada

Al Taweelah Alumina refinery operational readiness

United Arab Emirates

Regional Connector Transit Corridor

United States

Al Taweelah alumina refinery

United Arab Emirates (UAE)

See All