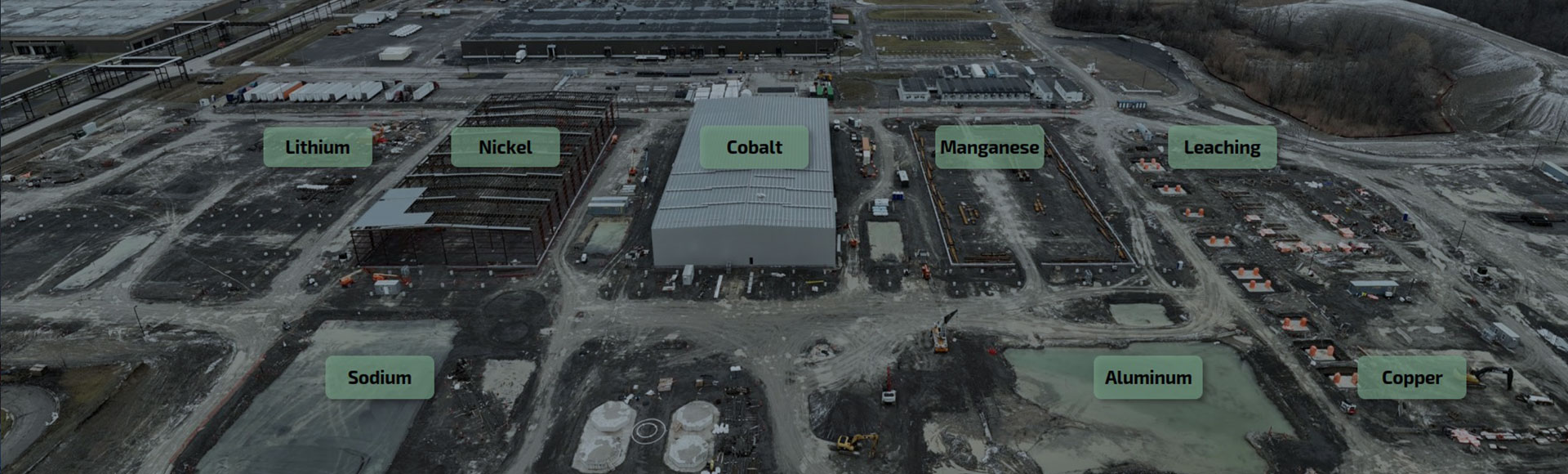

Li-Cycle Rochester Hub

Developing and constructing Li-Cycle's first commercial battery resource recovery facility

Li-Cycle | Rochester, New York, USA | 2022-2024

Expected to becomeNorth America's first commercial hydrometallurgical batteryresource recovery facility.

Will operate at acapacity of 35,000 tpa of black mass, equivalent to 90,000 tpa of lithium-ion batteries.

At start-up,will be North America's only source of battery-gradelithium carbonate.

Challenges

- In order to meet the demand for critical battery materials, Li-Cycle is establishing its first commercial hub facility to process recycled cathode and anode materials (referred to as "black mass") into battery-grade end products.

- The Rochester Hub is expected to be the first commercial hydrometallurgical battery resource recovery facility to produce battery-grade materials, including cobalt, nickel, and lithium, from the black mass produced from recycled lithium-ion batteries.

- Li-Cycle needed an engineering and procurement partner with extensive experience and expertise in hydrometallurgy to develop this first-of-its-kind facility.

Solutions

- 杠杆我们复杂的流程设计和大型专业ject implementation experience, alongside our deep knowledge of established hydrometallurgical processes and existing technologies to support detailed engineering efforts for the Rochester Hub.

- 孵化was engaged to provide project management services for detailed engineering, procurement, construction support, and commissioning planning.

- As of Q1 2023, completed approximately 65% of detailed engineering. Procurement is well advanced, with more than 90% of process equipment ordered.

Highlights

- Once operational, the Rochester Hub will be the first commercial facility in North America to produce battery-grade lithium carbonate from recycled lithium-ion batteries.

- The Rochester Hub is anticipated to have a processing capacity of 35,000 tonnes per annum (tpa) of black mass, which is the equivalent of approximately 90,000 tpa of lithium-ion batteries.

- Through Li-Cycle's Spoke & Hub network, manufacturing scrap and spent batteries are processed in various Spoke facilities across North America. The Spokes produce black mass, which is then processed at the Hub to produce battery-grade materials.

35,000tpa in black mass processing capacity.

65acres of land, including the warehouse.

~US$485million in capital costs.

270000年linear feet of piping.

2.6million linear feet of wire and cable.

30,000cubic yards of concrete.

3,500tonnes of structural steel.

4,200instruments.

65acres of land, including the warehouse.

~US$485million in capital costs.

270000年linear feet of piping.

2.6million linear feet of wire and cable.

30,000cubic yards of concrete.

3,500tonnes of structural steel.

4,200instruments.

How we can help you

If you have a problem that needs to be solved, please get in touch.

Related Projects

Technical Advisor for Electric Bus and Infrastructure Loans

York, Ontario, Canada

Wolbachia Mosquito Rearing Facilities

Brazil & Colombia

Tata Steel hydrogen-based steel manufacturing

IJmuiden, Netherlands

Mount Royal Tunnel double arch replacement

Montreal, Quebec, Canada

Minneapolis weathers the storm with a new parallel tunnel

Minneapolis, MN, USA

Highway 17 Noise Impact Assessment

Hewitson Creek, Ontario

MaineDOT Bus Electrification Project

Maine, USA

COVID Economic Recovery Plans

United Kingdom