Meadowbank Gold Project

Agnico-Eagle Mines Ltd. | Canada | 2007–2010

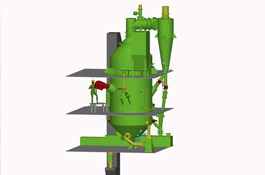

8,500 tpd

capacity gold concentrator

28 MW

diesel-power generation plant with heat recovery

US$272 million

CAPEX (Hatch's scope)

−50ºC

Arctic winter conditions

Challenges

- Design facilities for Arctic conditions: ultra-low temperatures, drifting snow in wintertime and wet ground, permafrost conditions in summer

- Manage the logistics of a remote air-and-barge-access location and a 10-week shipping season in mid-to-late summer

- Supply all power and heat from an on-site, diesel-power generation plant

- Operate in a remote, greenfield location with no existing support infrastructure of any kind

Solutions

- Provided detailed engineering, procurement, and construction support services for the 8,500 tpd gold processing facilities and site infrastructure, including power-generation plant

- Waste material from prestripping was used as bulk construction material for erecting dikes and for fill materials around the site

- Eight major buildings were erected during summer so concrete and equipment installation could continue indoors during the harsh Arctic winter conditions

- The power plant was designed to include a heat-recovery system, providing heat to the entire mine site complex

Highlights

- More than 50,000 tonnes of material and equipment were mobilized to the site over a purpose-built, 115 km, all-weather road from Baker Lake

- Equipment and construction materials were procured in time to be all shipped on barges during a short 10-week ice-free period in summertime

- Our procurement and logistics strategy helped meet the construction schedule and improved working conditions for contractors through the winter

- The diesel-fired power plant, heat-recovery, and heat-distribution systems that we designed were rigorous enough for Arctic conditions and resulted in cost savings and schedule improvements

Project numbers

US$272 millioncapital cost (Hatch's scope)8,500 tpdgold concentrator

28 MWdiesel-power generating plant

115 kmpurpose-built, all-weather road

40,000,000 Ldiesel-storage facility at Baker Lake

5,600,000 Ldiesel-storage & dispensing facility at the site

10bay truck shop & office complex

350person camp accomodations

50,000 tonnesof material and equipment shipped in 10 weeks

Services & technologies provided

What's your challenge?

Related projects

Gold mine in Western Australia

Australia

DST示范工厂

Canada

Twin Creeks Mercury Abatement Project

Nevada, USA

Tasiast Expansion Project

Mauritania

Twin Creeks Autoclave Tonnage Improvement

Nevada, USA

hthcom华体会

Saudi Arabia

Pueblo Viejo – Pressure Oxidation & Air Separation Project

Dominican Republic