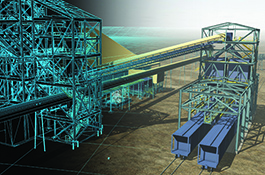

Mosaic New Wales MicroEssentials Conversion Project

Major expansion has fertilizer plant exceeding design capacity

Mosaic Fertilizer, LLC | USA | 2014-2016

1.2 million

man-hours with 0 LTIs

10%

under budget

65,000 ton

MicroEssentials product warehouse

Conversion

to MicroEssentials production

Challenges

- To meet the increasing demand for specialty crop nutrients, Mosiac needed to convert an existing dual-train, DAP granulation plant to produce their patented MicroEssentials line of products.

- Extensive modifications were required to the existing plants to convert them.

- The existing plant scrubber systems needed to be replaced and retrofitted for closed-loop scrubbing.

- Equipment ventilation and dust-collection systems needed to be redesigned to improve dust collection, handling, and recycling.

Solutions

- Execute detailed engineering, design, construction management, and commissioning services.

- Modify the existing plants to allow micronutrient receiving, storage, and feed systems; sulfur unloading systems with a sulfur pit; new 65,000-ton MicroEssentials product warehouse with an automated reclaimer; all associated utilities and infrastructure required to support the project.

- Replace the existing plant scrubber systems and retrofit them for closed-loop scrubbing.

- Redesign equipment ventilation and dust-collection systems to improve dust collection, handling, and recycling.

Highlights

- The East granulation plant started up in February 2016 and exceeded design capacity within two weeks.

- The West granulation plant started up in June 2016 and already exceeds design capacity. The overall project is approximately 10% under budget.

- 建设和现场人力超过1.2毫升lion man-hours.

- A total of 1,660 contractor personnel were provided with safety training for site access, and no lost time incidents were reported on this project.

Project numbers

1,660contractor personnel1.2 millionman-hours with 0 LTIs

What's your challenge?

Related Projects

Li-Cycle Rochester Hub

Rochester, New York, USA

Phosphoric Acid Plant Expansion

United States

Faustina Brownfield Fertilizer Plant

United States