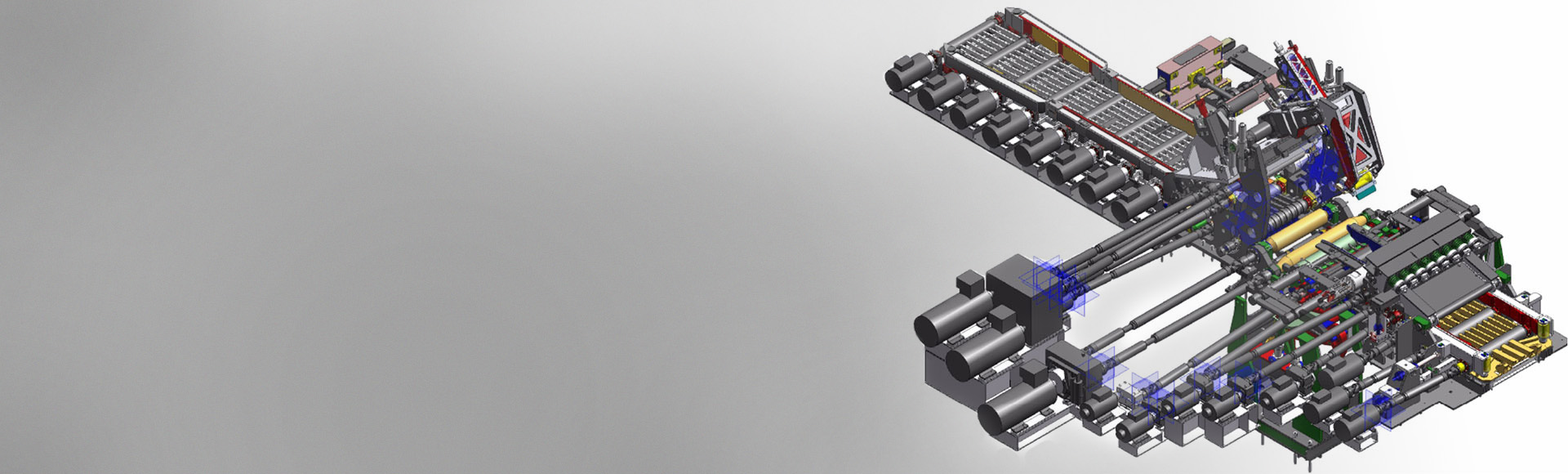

Zaporizshstal 1680 mm Coilbox™

Unlocking performance in a hot strip mill

Zaporizhstal Integrated Iron-and-Steel Works | Ukraine | 2005–2007

Shortest time between coils

Less than 5 seconds gap-time capability to deliver coils to the FM

Custom foundation Coilbox™

Challenges

- Zaporizhstal was modernizing its hot strip mill (HSM) with new reheat furnaces able to handle larger slab lengths while smaller existing furnaces continued to handle small slabs.

- The mix of slab sizes created the need for a Coilbox™ that could roll the larger slabs and handle smaller ones with as little as 5 seconds between bars at the finishing mill.

- The older HSM had a very shallow mill flume and a mostly manual operation, creating additional challenges.

Solutions

- With a custom-designed, mandrelless Coilbox™, Zaporizhstal was able to coil and uncoil small and large transfer bars, maintaining a gap at the finishing mill of less than 5 seconds.

- The thermal advantages of the Coilbox™ were achieved with the mandrelless transfer design, high processing speeds in the Coilbox™, and the implementation of energy-saving heat shields.

Highlights

- The Zaporizhstal Coilbox™ can deliver coils to the finishing mill with the shortest gap-time: less than 5 seconds.

- The Zaporizhstal Coilbox™ has a small foundation footprint compared with mandrelless transfer coilboxes.

Project numbers

5-second交付y intervals between coils at FM5 kg/mmsmall coils can be processed

What's your challenge?

Related Projects

Tata Steel hydrogen-based steel manufacturing

IJmuiden, Netherlands

hth官方网址

Asia

SunCoke South Shore Project

United States

USS Gary Works No. 8 Blast Furnace Reline

United States

Anling 1700 mm Coilbox™

China

Clairton Improvement Project

United States

hth官网

South Africa

US Steel Mon Valley Works FFF System

United States